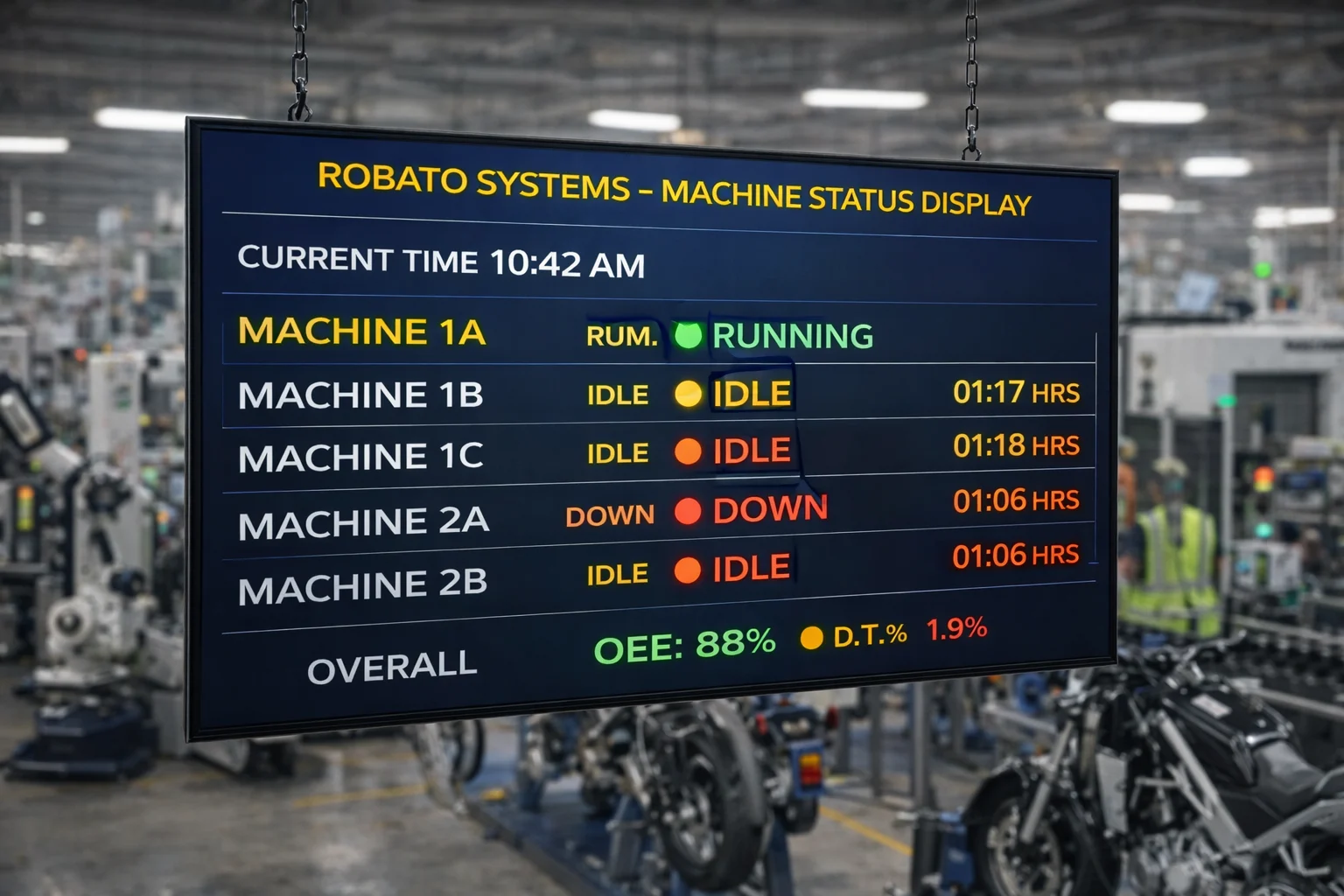

The Robato Machine Status Display Board gives your team instant visual feedback about the condition of every machine on the shop floor. Using bright industrial LED display boards or Smart TV dashboards, you can see at a glance which machines are Running, Idle, in Breakdown, under Maintenance or Setup.

A Machine Status Display Board is a digital display used in factories to show live machine states. Instead of walking around to check each machine, supervisors can simply look at one central board and instantly understand the condition of every critical asset.

Typical states shown on the board include:

ROBATO SYSTEMS

Experience cutting-edge production monitoring solutions

Book a free trial and experience the difference

Choose the right display board for your factory needs

Dedicated LED board for one critical machine or line, showing status colour and simple text.

One large board showing the live status of 4, 8, 12 or more machines in a grid or table format.

Displays the status of machines grouped by department, cell or production line.

Uses a Smart TV or large commercial display instead of LED-only hardware. Ideal for control rooms, supervisor cabins and meeting rooms.

Uses colour-coded segments (green, yellow, red, blue, white) to highlight machine condition.

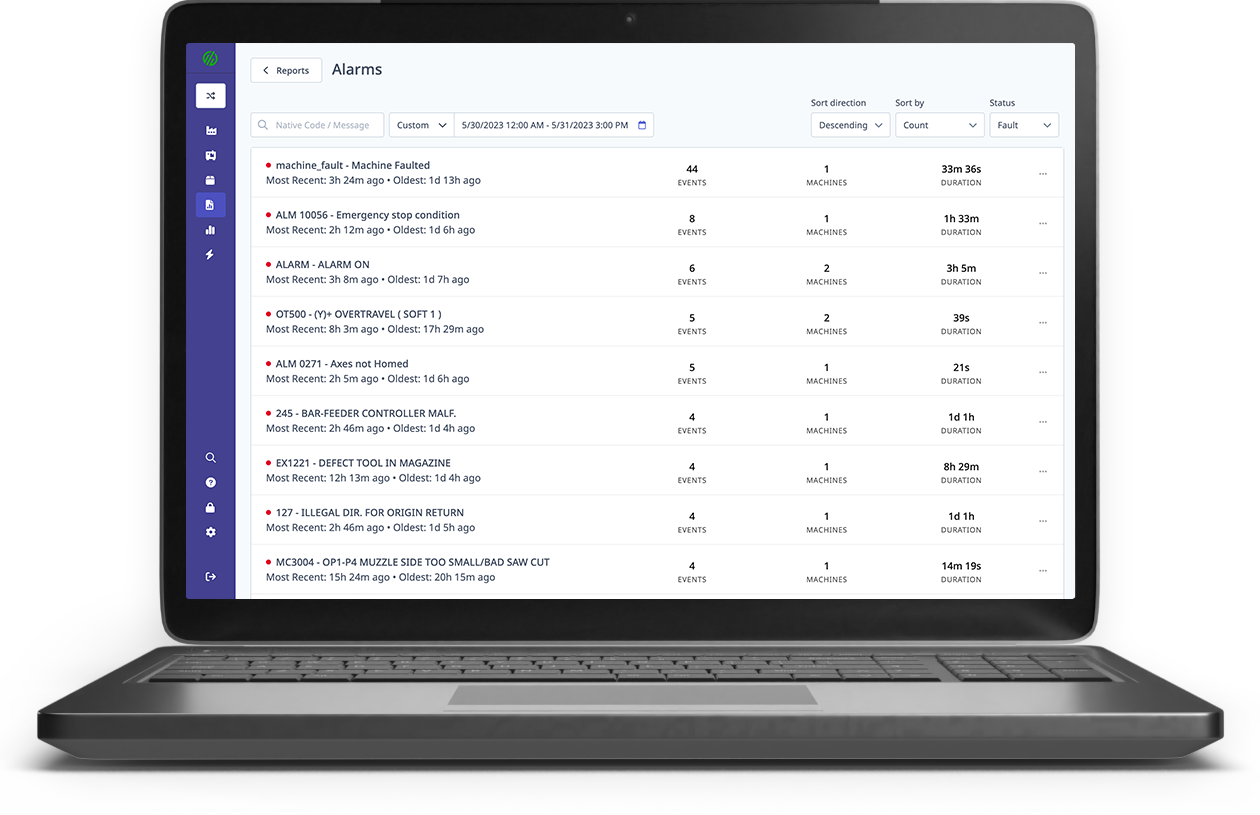

The Machine Status Display Board can receive data from multiple sources

PLC digital outputs – direct machine status signals

Sensors – running/idle detection via pulse timing

Production Counter devices – integrated status and counts

Andon buttons – operator-initiated breakdown or help calls

Maintenance system – planned maintenance windows

Cloud / On-Prem Monitoring Software

WiFi / Ethernet

RF Wireless (via gateway)

MQTT, HTTPs, WebSocket

ROBATO SYSTEMS

Experience cutting-edge production monitoring solutions

Book a free trial and experience the difference

Everything you need for real-time machine visibility

Running / Idle / Breakdown states visible at a glance.

View multiple machines on a single board.

Quick recognition with industry-standard colors.

Seamless integration with monitoring systems.

Choose the display that fits your environment.

Control from anywhere.

No manual input required.

Tailored to your factory.

LED Board / Smart TV Dashboard

Red, Green, Amber, RGB

WiFi, Ethernet, RF Wireless

PLC, sensors, Andon, server

Custom (2ft – 10ft+)

Android App, Web, PLC I/O

Wall, hanging, structure mount

Combine Downtime Monitoring, OEE Monitoring, Andon Systems and the Robato Machine Status Display Board to build a truly transparent and responsive shop floor.