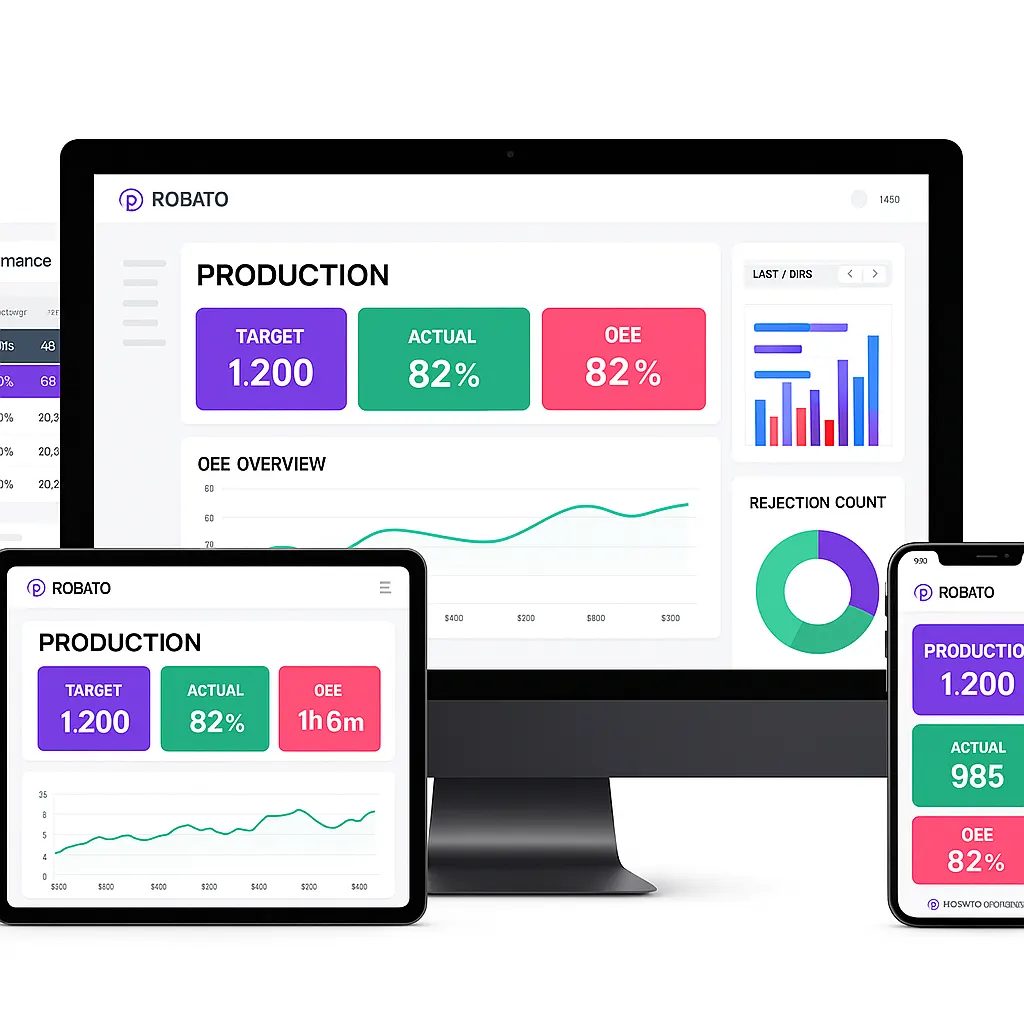

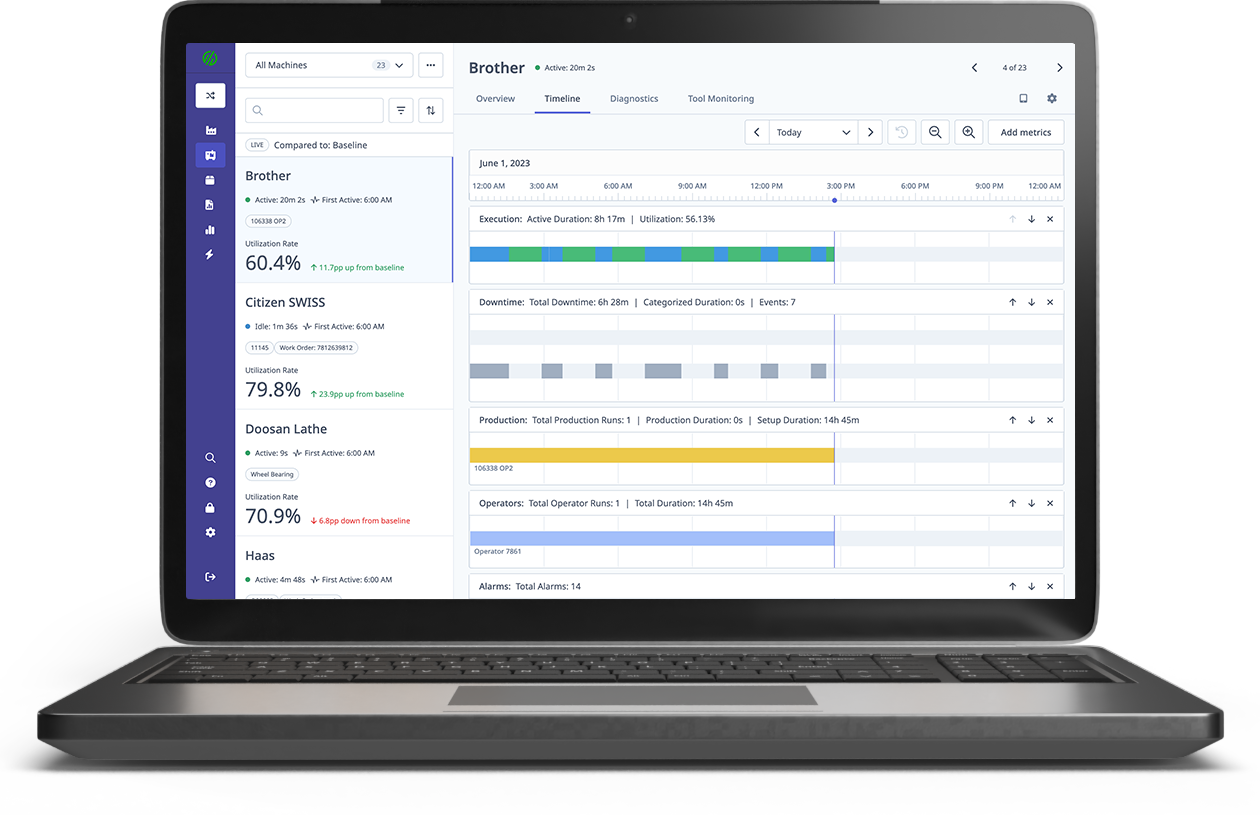

The Robato Production Downtime Monitoring System helps factories identify and eliminate machine stoppages, idle time, breakdowns and micro-downtime. It delivers live visibility of downtime events using LED counters, PLC signals, sensors, Andon buttons, tower lights, cloud dashboards and on-prem monitoring.

Even a small 5-minute stop repeated throughout the shift leads to massive production loss. Most factories face:

Robato's Downtime Monitoring Software solves these issues with automated detection and instant alerting.

Let Robato Systems transform your business with cutting-edge automation solutions. Book a free consultation and see the difference.

From detection to analytics in four steps

The system detects downtime through:

When downtime occurs, alerts reach:

Operators can enter reasons using:

The software generates:

ROBATO SYSTEMS

Experience cutting-edge production monitoring solutions

Book a free trial and experience the difference

Everything you need for real-time downtime tracking and analysis

Via sensors, counters & PLCs.

On LED boards & Smart TVs.

From cycle-time variation.

Via mobile/HMI.

With timestamps.

If issue unresolved.

Complete visibility.

Flexible options.

Downtime feeds directly into Availability.

With MES/ERP systems.

PLC, counters, sensors, Andon

WiFi, Ethernet, MQTT, HTTPs

Cloud SaaS / On-Prem

Web, Android, Smart TV

Machine, Line, Plant, Shift

OEE, Andon, Production

ROBATO SYSTEMS

Experience cutting-edge production monitoring solutions

Book a free trial and experience the difference

Combine Andon System, OEE Monitoring and Cloud Production Monitoring with the Downtime Monitoring System to achieve complete shop-floor visibility.